|

|

|

|

| Slimcure (Space Saving UV Curing System) |

|

When there is a lack of space for curing photosensitive varnishes and

inks, it becomes necessary to use UV units installed right on the

printing machine. Hansa's Slimcure system is suitable to be placed on

almost every kind of printing machine. It consists of an aluminium box

with air-cooled UV lamps.

One of the main problems in placing a UV system on

a printing machine is the different mechanical features of different

printing machines that often hinder the correct placement of the UV

source. Hansa's Slimcure has a very small multi-elliptical reflector

with very good focusing at different distances, to fit every type of

mechanical construction. |

|

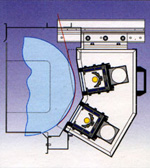

The lamps that Hansa uses in its units are the result of a thorough

research and refinement over the past 20 year period. These lamps can

operate at 80 W/cm or 120 W/cm, or if required, at both capacities.

The lamps are air-cooled.

Each UV unit can be equipped with a swivelling

device to prevent overheating and conveyor belts' wear, in case of

line stop or emergency.

|

|

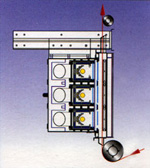

The electrical equipment is installed inside a

control cabinet built according to ISO standards. It has a fan

ventilation system. The lamps' power supply units are easily reachable

and follow existing standards. Optionally, it is possible to install

an in-line display equipped with troubleshooting system. It can

perform standard and special control operations like:

-

Separated visual indication of failures

-

Machine production per hour

-

Daily production

-

Advancement of production order

-

Conveyor speed

|